5. Leak Detection Pump Operation Simplified How Does It Work?

Explanation

Leak Detection Pump Operation Simplified How Does It Work:

Hey there! Ever wondered how cars make sure they don't have any leaks that could cause problems? That's where the "Leak Detection Pump" (LDP) comes in. Let me explain how it works.

Imagine your car is like a big balloon, and it's important to make sure there are no tiny holes in it. These holes could let out gases that shouldn't escape. That's where the LDP comes into play.

- Collecting Vapors: The LDP's job is to collect something called "vapors." Think of vapors as tiny, invisible gas particles that can escape from different parts of your car, like the fuel tank or the engine.

- Storing Vapors: The LDP collects these vapors in a special container, "canister" like a little jar. It doesn't let the vapors go anywhere else.

- Checking for Leaks: Now, the LDP becomes a detective. It starts to look for any holes or leaks in your car's balloon-like system "EVAP". If it senses that the vapors are disappearing too quickly, it knows there might be a leak.

- Alerting the Car's Brain "PCM": The LDP isn't just a detective; it's like a messenger too. It tells the car's brain (the computer inside your car) that there might be a leak.

- Fixing the Issue: Once the car's brain knows about the possible leak, it can take action. It might turn on a warning light on your dashboard, telling you to get your car checked by a mechanic.

So, the Leak Detection Pump is like a guardian for your car, making sure it doesn't lose any important gases and keeping you safe on the road. It's all part of the clever technology that makes our cars run smoothly!

Leak Detection Pump Operation Simplified How Does It Work

Leak Detection Pump Operation Simplified

What is the main purpose of the EVAP Leak Detection Pump

Link to Video of their Location

Leak Detection Pump Operation Simplified How Does It Work

The main purpose of the EVAP (Evaporative Emission Control System) Leak Detection Pump in a car is to ensure that there are no leaks in the vehicle's fuel vapor system. This system is designed to capture and store fuel vapors that can escape from the fuel tank and other parts of the fuel system, preventing them from being released into the atmosphere as harmful emissions.

Here's how the EVAP Leak Detection Pump works:

- Vapor Collection: The EVAP system collects the fuel vapors that would otherwise evaporate into the air. These vapors are captured in a charcoal canister.

- Sealing the System: The EVAP system ensures that the fuel vapor system is sealed tightly to prevent any leaks. Even tiny leaks can contribute to air pollution and harm the environment.

- Pressure Testing: Periodically, the Leak Detection Pump pressurizes the EVAP system to a specific level. It checks if the pressure remains stable. If there is a leak, the pressure will drop.

- Detecting Leaks: If the Leak Detection Pump detects a drop in pressure, it signals the car's computer (ECU or PCM) that there may be a leak in the system.

- Alerting the Driver: The car's computer can activate the "Check Engine" light on the dashboard to alert the driver to the potential problem. This indicates that the vehicle should be inspected by a mechanic to identify and repair any leaks.

In summary, the main purpose of the EVAP Leak Detection Pump is to help prevent harmful fuel vapors from escaping into the environment and to maintain the integrity of the vehicle's emissions control system by detecting and alerting the driver to any leaks that may develop in the fuel vapor system. This system helps reduce air pollution and ensures that the vehicle meets emissions standards.

How does the Leak Detection Pump (LDP) Work

Leak Detection Pump Operation Simplified How Does It Work:

- Collecting Fuel Vapor: When your car's engine is turned off, fuel vapor from the fuel tank and other parts of the fuel system can escape into the atmosphere. To prevent this, the EVAP system captures these fuel vapors and stores them in a charcoal canister.

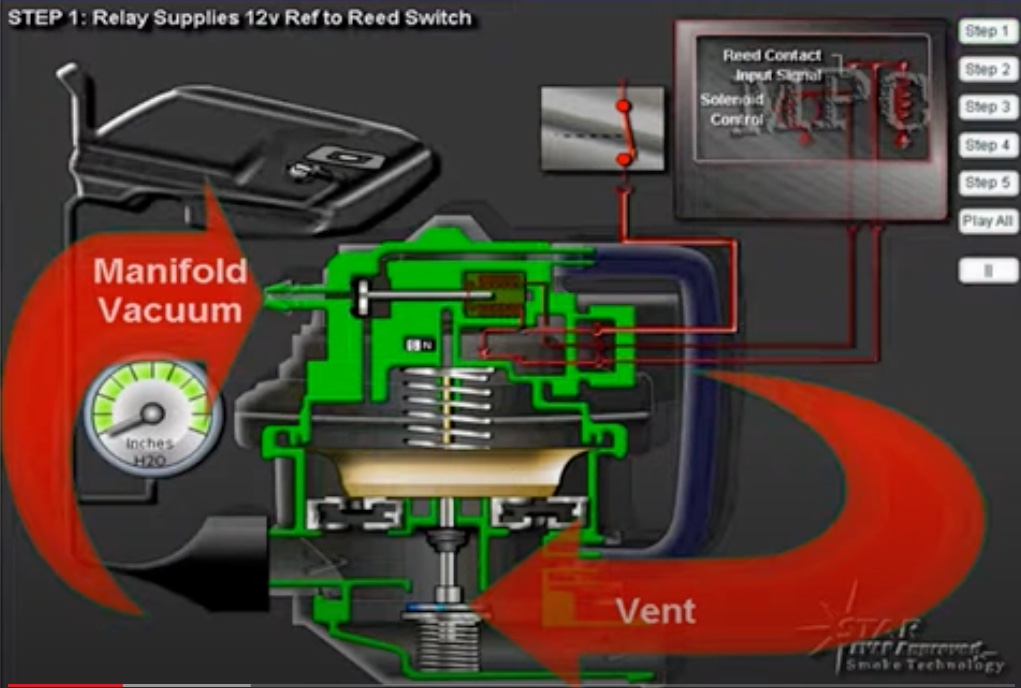

- Pressurizing the System: The LDP's primary function is to pressurize the EVAP system to a specific level, typically around 7.5 inches of water (abbreviated as 7.5" H2O). It uses engine vacuum, which is a suction created by the engine, to do this.

- Building Pressure: The LDP is connected to the EVAP system through a series of hoses. When it's time to check for leaks, the LDP closes a valve that connects the EVAP system to the charcoal canister and begins pumping air into the EVAP system. This introduces clean air, pressurizing the system to the desired 7.5" H2O level.

- Monitoring Pressure: While the LDP is pumping air into the system, it closely monitors the pressure. It has a pressure sensor that measures the pressure inside the EVAP system.

- Detecting Leaks: If there are no leaks in the EVAP system, the pressure will remain stable at 7.5" H2O. However, if there's a leak, the pressure will drop because air is escaping through the leak. The LDP can detect even tiny drops in pressure.

- Alerting the Car's Computer: When the LDP detects a drop in pressure, it sends a signal to the car's computer (Electronic Control Unit "ECU" or PCM ). The ECU then activates the "Check Engine" light on your dashboard, alerting the driver to the potential problem.

In summary, the Leak Detection Pump works by using engine vacuum to pump clean air into the EVAP system, pressurizing it to a specific level (7.5" H2O). It then monitors the system's pressure and detects leaks by observing any drops in pressure. If a leak is detected, it triggers the "Check Engine" light to alert the driver that there might be an issue with the EVAP system that needs attention. This helps reduce air pollution by ensuring that fuel vapors are properly contained and not released into the environment.

Have A Great Story About This Topic?

Have you ever had a problem with a Leak Detection Pump on a certain vehicle please share your experience. If not explain what you have learned from this page on the LDP.

What Other Visitors Have Said

Click below to see contributions from other visitors to this page...

Henry Honarchian tech/inspector Not rated yet

I once had a Ford that would not build pressure and found the leak detection pump at fault

Chrysler Leak Detection Monitor Sequence

Leak Detection Pump Operation Simplified How Does It Work:

The Chrysler Leak Detection Pump (LDP) monitor sequence is a specific set of steps that the vehicle's onboard computer (Engine Control Module or ECM) follows to check the functionality of the LDP and the Evaporative Emission Control System (EVAP). This sequence is important for ensuring that the vehicle complies with emissions standards and does not have any leaks in the EVAP system. Here's an explanation of the typical Chrysler LDP monitor sequence:

- Key On Engine Off (KOEO): This is the initial step. When you turn the vehicle's ignition key to the "On" position (but don't start the engine), the ECM prepares to perform the LDP monitor.

- LDP Self-Test Initiation: The ECM initiates a self-test of the LDP system. This test checks if the LDP itself is functioning correctly.

- LDP Valve Closed: The ECM commands the LDP to close a valve that connects the EVAP system to the charcoal canister. This seals the EVAP system from the atmosphere.

- Pressure Build-Up: The ECM then activates the LDP to pump air into the EVAP system. The LDP pumps air into the system, pressurizing it to a specific level (often around 7.5 inches of water, abbreviated as 7.5" H2O).

- Pressure Stabilization: Once the desired pressure is reached, the ECM monitors the system's pressure to ensure it remains stable. If there are no leaks in the EVAP system, the pressure should stay constant.

- Pressure Decay Check: The ECM continues to monitor the system for a specified period (usually several seconds) to see if the pressure decreases. If the pressure drops, it indicates a potential leak in the EVAP system.

- LDP Self-Test Completion: After completing the pressure checks, the ECM evaluates the results. If it detects a significant pressure drop, it may trigger a diagnostic trouble code (DTC) related to the EVAP system, turning on the "Check Engine" light on the dashboard.

- Data Recording: The ECM records relevant data about the LDP monitor sequence and any detected issues. This data can be retrieved later by a mechanic using a diagnostic tool.

- Monitoring Cycles: Leak Detection Pump Operation Simplified How Does It Work. The LDP monitor sequence typically runs during specific driving conditions, known as "drive cycles." The ECM may require multiple successful drive cycles to confirm the absence of any leaks before resetting the "Check Engine" light. In summary, the Chrysler LDP monitor sequence is a series of steps initiated by the vehicle's computer to check the integrity of the LDP and the EVAP system. It pressurizes the system, monitors the pressure, and looks for pressure drops that could indicate a leak. If a problem is detected, it triggers the "Check Engine" light, prompting the driver to address any potential issues with the EVAP system.

Diagnostic Module - Tank Leakage Pump

Leak Detection Pump Operation Simplified How Does It Work:

The Diagnostic Module - Tank Leakage Pump (DM-TLP), often referred to as the "tank leakage detection pump," is an essential component in the Evaporative Emission Control System (EVAP) of a vehicle. Its primary function is to monitor and detect any leaks or abnormalities in the fuel vapor system. Here's how it operates and how diagnostics are performed:

Operation of the DM-TLP:

- Sealing the EVAP System: When the vehicle's engine is off, the EVAP system is pressurize. The DM-TL system does not have a fuel tank pressure sensor or canister vent valve.

- Diagnostic Module: The DM-TL consist of a motorized pump a solenoid sealing valve, a .020 inch diameter internal reference orifice. When the correct enable criteria is meet the DM-TL is activated to check for system leakage.

- DM-TL: Relies on current flow and pressure over time to monitor for leaks

- Pressure Stabilization: The motorized air pump pressurizes the EVAP system producing a current draw that the PCM reads to determine if there is a leak

- Leak Detection: The DM-TL main job is to detect leaks in the EVAP system. The built in .020" reference orifice provides the PCM the current draw of the air pump motor to determine the pass/fail conditions during a leak check.

- Alerting the Vehicle's Computer: When the DM-TL detects a pressure drop indicative of a leak, it communicates this information to the vehicle's onboard computer (Engine Control Module or ECM).

- Diagnostic Trouble Codes (DTCs): The ECM, upon receiving the information from the DM-TLP, can trigger specific Diagnostic Trouble Codes (DTCs). These codes provide information about the nature of the issue, helping mechanics identify and fix the problem.

Have A Great Story About This Topic?

Have you ever had a problem with a Diagnostic Module - Tank Leakage Pump on a certain vehicle please share your experience. If not explain what you have learned from this page on the Diagnostic Module - Tank Leakage Pump.

Summary

- The DM-TL pressurizes the EVAP system with the key off

- It continuously monitors the pressure over time to detect any leaks in the fuel vapor system.

- The built in reference is 0.20" inch

- If a leak is detected, it triggers the "Check Engine" light and stores Diagnostic Trouble Codes (DTCs).

- Mechanics use diagnostic tools to retrieve DTCs and diagnose the specific issue.

- Visual inspections may also be performed to identify physical problems.

- Overall, the DM-TL helps ensure the proper functioning of the EVAP system, reducing harmful emissions and maintaining vehicle performance.

SMOG UPDATE ONLINE CLASS CLICK HERE FOR ACCESS Power Point Presentation

Understanding How Natural Vacuum Leak Detection Work

CLASS SCHEDULES

Emission Control 1:

B.A.R. Smog Check

Inspector Level 1

(Inspector "Smog" License):

Engine Fundamentals

8am - 12:15 pm

Summer Class

7/5/2022 -8/5/2022

Class # 799065

Emission Control 2:

B.A.R. Smog Check

Inspector Level 2

(Inspector "Smog" License):

Rules and Regulations

8am - 12:15 pm

Summer Classes

7/5/2022 - 8/5/2022

Class # 799067

Engine Performance 1:

8am - 12: 15 pm

Date: TBD

Class # 799069

Engine Performance 2:

B.A.R. Specified Diagnostic

and Repair Training

(Repair "Smog" License)

Time: TBD

Date: TBD

Class # 799071

Emission Control 1

(Inspector "Smog" License):

5:00pm - 8:45 pm

Date: TBD

Class # 799065

Emission Control 2:

(Inspector "Smog" License):

5:00pm - 8:45 pm

Date: TBD

Class # 799065

Exhaust Emissions (Update Class):

5:30 pm - 8:45 pm

Tuesday nights:

Dates: coming soon

Class # 796070